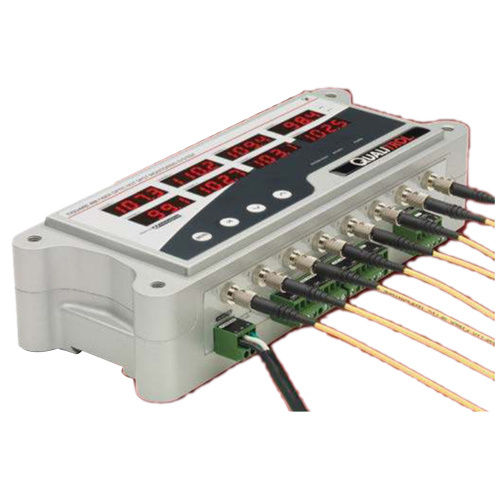

Single Gas DGA Monitor

उत्पाद विवरण:

- एप्लीकेशन Industrial

- सुरक्षा स्तर IP54

- आउटपुट टाइप Normal

- वारंटी Yes

- Click to view more

सिंगल गैस डीजीए मॉनिटर मूल्य और मात्रा

- यूनिट/यूनिट

- यूनिट/यूनिट

- 100

सिंगल गैस डीजीए मॉनिटर उत्पाद की विशेषताएं

- Industrial

- Yes

- IP54

- Normal

सिंगल गैस डीजीए मॉनिटर व्यापार सूचना

- कैश ऑन डिलीवरी (COD)

- प्रति महीने

- दिन

- ऑल इंडिया

उत्पाद विवरण

TECHNICAL SPECIFICATIONS

| DGA Method: Solid-state H2 sensor immersed directly in the oil | Hydrogen (H2 ) | Accuracy | Repeatability | Range |

|

| ±15% or ±20 ppm | ±5% or ±10 ppm | 20 – 10,000 ppm | |

|

| 1) Lower Detection Limit 20 ppm |

|

| |

| Additional Monitoring Options (Optional) |

| Accuracy |

| Range |

|

| Moisture-in-Oil | ±5% |

| 0-100% RS |

|

| Oil Temperature | ±2°C (typically) |

| -40°C to +120°C |

| Gas Analysis Parameters | Oil Sampling Rate | Continuous oil sampling; gas analysis is reported every 30 minutes | ||

|

| Data Management | Data is date and time stamped; up to five years of data is stored in memory | ||

| Display | Integrated display of H2 Level, H2 Rate of Change (ROC), Moisture (optional) and Service Codes. | |||

| Alarms | Relay Contact Ratings | Max switched Power 100 W or 600 VA, Max switched Current 3 A, Max switched Voltage 150 VDC or 300 VAC | ||

|

| 3 DGA Relays | Three (3) programmable alarm relays for H2 Level (ppm), H2 Rate of Change (ROC) (ppm/day), and optional Moisture | ||

|

| 2 Alarm Relay | Two (2) alarm relays for power and service status | ||

| External Inputs | Digital Inputs | RS232 for configuration utility and diagnostics; USB Mini B for direct connection with computer or USB Thumb Drive | ||

|

| Analog Inputs | Two (2) analog 4-20 mA inputs for optional moisture probe | ||

| Communications | Standard Interfaces | RS232 / 485, USB 2.0, Three (3) analog 4-20 mA outputs for H Level, H 2 2 Rate of Change (ROC) and optional Moisture | ||

|

| Supported Protocols | DNP3 and Modbus | ||

| Environmental Specifications | Operating Temperature | -50°C to +55°C |

|

|

|

| Oil Temperature | -20°C to +105°C |

|

|

|

| Oil Inlet Pressure | 0 to 100 psi (0 to 7 bar) |

|

|

| Physical Specifications | Product Dimensions | HxWxD: 9.2 in x 9.9 in x 12.3 in (23.4 cm x 25.1 cm x 31.2 cm) | ||

|

| Product Weight | 9 lb (4 kg) | ||

|

| Enclosure Rating | NEMA 4X, IP66 | ||

| Input Power Requirements | Voltage | 100 - 240 VAC |

|

|

|

| Frequency | 50/60 Hz |

|

|

|

| Current | 0.8 A max. |

|

|

| Radiated and Conducted Emissions | Radiated Emissions | EN 61326-1: 2006 |

| CISPR 11: 2009 A1: 2010 Class A |

|

| Conducted Emissions | EN 61326-1: 2006 |

| CISPR 11: 2009 A1: 2010 Class A |

|

| Current Harmonics | EN 61000-3-2: 2006 A1: 2009 A |

| EN 61000-3-2: 2006 A1: 2009 Class A |

|

| Voltage Fluctuations | EN 61000-3-3: 2008 |

| EN 61000-3-3: 2008 Class A |

| Radiated and Conducted Immunity | ESD | EN 61326-1: 2006 |

| IEC61000-4-2: 2009 |

|

| Radiated Immunity | EN 61326-1: 2006 |

| IEC61000-4-3: 2006 A2: 2010 |

|

| EFT | EN 61326-1: 2006 |

| IEC61000-4-4: 2004 A1: 2010 |

|

| Surge | EN 61326-1: 2006 |

| IEC61000-4-5: 2006 |

|

| Conducted RF Immunity | EN 61326-1: 2006 |

| IEC61000-4-6: 2009 |

|

| Magnetic Field Immunity | EN 61326-1: 2006 |

| IEC61000-4-8: 2010 |

|

| Voltage Dips & Interrupts | EN 61326-1: 2006 |

| IEC61000-4-11: 2004 |

|

|

| IEC 60255-21-1 |

|

|

| Safety |

| IEC 61010-1 |

|

|

|

|

| IEC 61010-2-81 |

|

|

|

|

| UL 61010-1 (2nd Edition) |

|

|

|

|

| CSA-C22.2 No. 61010-1-04 |

|

|

FAQs of Single Gas DGA Monitor:

Q: What is the Single Gas DGA Monitor?

A: The Single Gas DGA Monitor is a device used to measure the concentration of gases in the air. It is designed for industrial applications and has a protection level of IP54.Q: What gases does the Single Gas DGA Monitor measure?

A: The Single Gas DGA Monitor is capable of measuring a single type of gas, such as carbon monoxide or nitrogen dioxide.Q: What is the output type of the Single Gas DGA Monitor?

A: The output type of the Single Gas DGA Monitor is normal.Q: Does the Single Gas DGA Monitor come with a warranty?

A: Yes, the Single Gas DGA Monitor comes with a warranty.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese